Mindblown: a blog about philosophy.

-

Let’s Get Caught Up

Anyone that knows me knows that I’m always up to something. I’m hopelessly obsessed with learning, especially learning to make things. That’s one of the main purposes of this blog, to document my those adventures. And while I’ve been constantly making since the inception of this blog, I’ve done a poor job of documenting the…

-

Book: How To Change Your Mind by Michael Pollan

How to Change Your Mind: The New Science of Psychedelics by Michael Pollan My rating: 5 of 5 stars It changed my mind! This book details how psychedelics have been grossly misrepresented and misunderstood in our society at large. Because of this misrepresentation, we have lost decades in which we could have been conducting legitimate…

-

Hello Abby, Well Hello Abby!

Last week we welcomed Abby, a 4 month old GSD (German Shepard Dog) into our home and into our lives. She has a very sweet personality and is extremely well trained for being only 4 months old. Bringing a dog into one’s life is a big responsibility, but when this opportunity presented itself, if felt…

-

Making Lemons into Limonada

I started to make a coin ring out of a 1958 Peso. As you can see from the photo to the left, things did not turn out as expected. The peso coin from 1957-1967 is 10% fine silver and 70% copper and 10% Zinc and Nickel. So I was a bit surprised with it cracked…

-

Change What You Wear. Change That You Wear!

Who doesn’t like cool jewelry? For nearly as long as homo sapiens have walked the earth, we have sought to adorn ourselves with nice looking things. Coins, on the other hand, are a relatively new invention. The oldest on record are about 2700 years old. Now both are brought together into a sort of “you…

-

He is Groot!

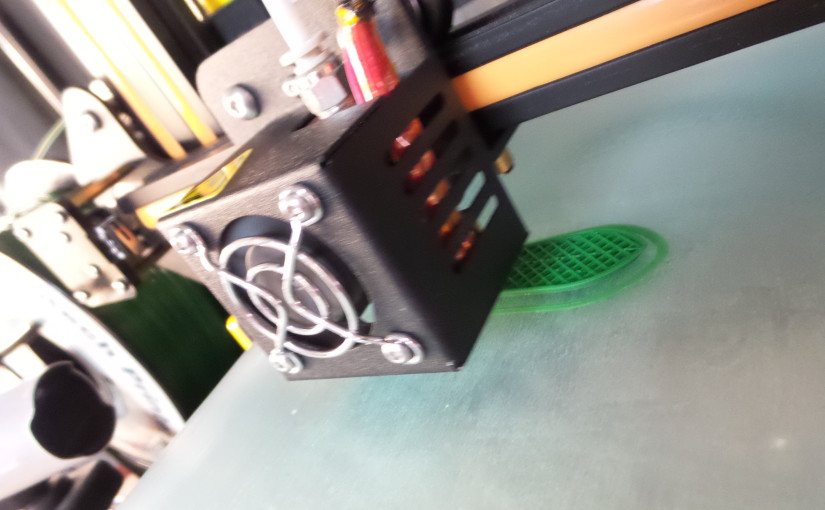

When my 3D printer isn’t printing…I start feeling a little antsy. After getting the printer for Christmas from my lovely, generous, and extremely intelligent wife, I spent the first few days/weeks figuring out how to make the thing work. Each day brought several hundred revelations. A 3D printer It’s not like a modern inkjet or…

-

Welcome to the “Art of Making It” Website

First posts are probably the hardest to write. Where do you start? At the beginning of course! But where does the beginning really begin? That’s the hard part… It all started back in 1969 when my mother and father…wait…that is obviously a little too far back. Okay, fast forward a few years. I’ve always loved…

-

Basics: Transistors and the Careful Placing of Impurities

(Editors Note: this blog post was first published on a mytronx.com, which has now been merged into AOMI.com). This YouTube video from the Acme School of Stuff (circa 1988) is a blast from the past. Despite it’s age, the info is presented as well as I have ever heard. It’s a brief introduction to electronics,…

-

Basics: Vacuum Tubes

(Editors Note: this blog post was first published on a mytronx.com, which has now been merged into AOMI.com). When I was a kid, I knew that televisions, radios and all sorts of electronics used vacuum tubes prior to the invention and widespread use of transistors. In fact, the black and white television on which I…

-

First Boards Have Arrived

(Editors Note: this blog post was first published on a mytronx.com, which has now been merged into AOMI.com. The board has now been renamed S2Duino. S2 stands for either “single sided” or “super simple.” This post is published exactly as it appeared). On Saturday, the first batch of boards arrived. While these are not the…

Got any book recommendations?